Space-Based Solar Power (SBSP) is currently being researched and developed in Europe, United States, China, Australia, Russia, South Korea and Japan. These ongoing SBSP efforts are testimony to the growing worldwide recognition of the potential contribution of SBSP to solving the world’s worsening climate and energy problems. If these efforts continue, they will lead to the development of a series of increasingly powerful test-satellites that will be needed before a major investment of the order of billions of Euros/Dollars will become feasible.

All current Space Power Satellite (SPS) concepts are designed to be launched from the surface of Earth and have launch masses between 2,000 and 10,000 metric tonnes (MT) per GW. Consequently, installing a single 1-GW SPS into High Elliptical (HEO) or into Geostationary (GEO) orbit around Earth will require 100’s of launches by a reusable, heavy lift launch system such as SpaceX’s Starship or China’s Long March 9 which are currently under development but not yet operational. Another consideration is the impact on the atmosphere by launching thousands of rockets that will be needed to deploy SPS on the scale of multiple hundreds of GWs needed to become a viable energy alternative to terrestrial energy systems. This crucial point needs to be emphasized if SBSP is to be considered as a sustainable long-term source of clean energy that does not produce harmful pollution. Therefore, significant GW-scale SPS systems cannot be launched only from Earth without seriously impacting the atmosphere.

Consequently, in order for SBSP to become acceptable and successful, it will require the establishment of SPS manufacturing facilities on the Moon. This lunar infrastructure can be used, not only to produce SPS components, but in an earlier stage also for the in-situ production of rocket propellant. Although the initial investment would be slightly higher than Earth-only launched SPS systems, the self-accelerating flywheel-effects in the process of building up a lunar economy, would come into operation quite early and would make the whole system more robust and less dependent on political and economic developments on Earth.

This gives Astrostrom GmbH a unique position in this dynamic field of SBSP development as Astrostrom is the only company that is currently pursuing the approach to manufacturing SPS components on the Moon from lunar materials. Astrostrom’s approach would greatly mitigate both the launch capacity bottleneck and the environmental impacts associated with SPS designs that only rely on Earth-launched systems, while also reducing the costs of manufacturing future solar power stations for servicing the multi-trillion terrestrial energy market. However, the space power community has not yet fully embraced the importance of the lunar option for manufacturing Solar Power Satellites on a large scale.

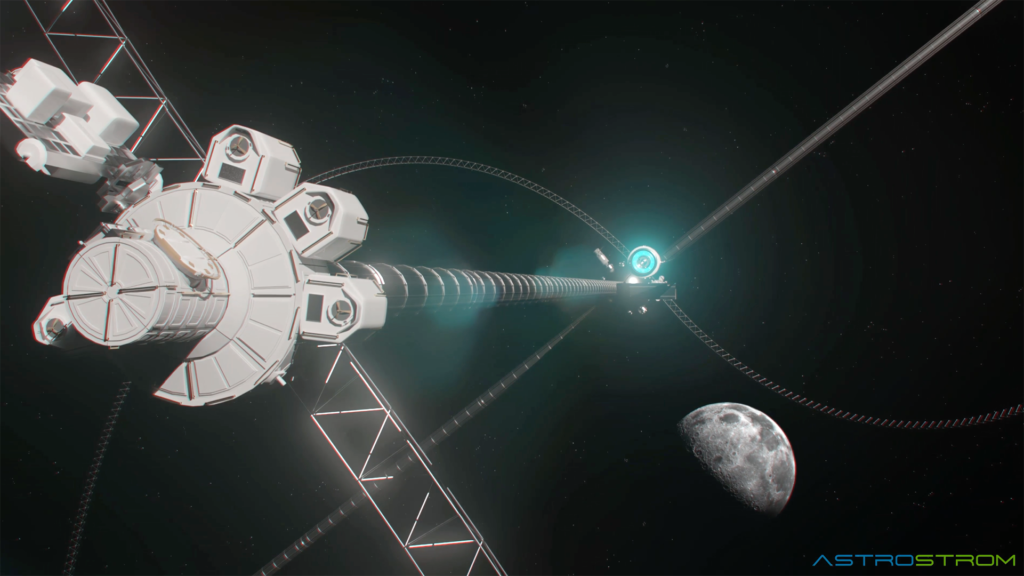

The Greater Earth Lunar Power Station (GE⊕-LPS)

In the framework of the European Space Agency’s (ESA) open call “Clean Energy from Space” [ESA, OSIP, 2020] 1 which sought novel ideas related to SBSP systems, Astrostrom GmbH was awarded a contract to investigate the feasibility of a “Greater Earth Lunar Power Station (GE⊕-LPS)” manufactured on the Moon and assembled at the Earth-Moon Lagrange Point 1 (EM-L1) to provide power from lunar orbit to operations on the surface of the Moon. Once the initial station is in operation, the production facilities on the lunar surface encompassing beneficiation, processing, and fabrication could then be rapidly scaled-up to produce additional Solar Power Satellites (SPS) to be shipped into Earth orbits to deliver clean, baseload, solar-generated microwave energy to Earth. The results of this study were published by ESA in May 2023 [ESA, 2023] 2,3,4,.

Astrostrom’s approach should not be confused with using SPS for Moon-only power requirements, or the concept of beaming power directly from the Moon to Earth, as several earlier studies have suggested. The study title “The Greater Earth Lunar Power Station (GE⊕-LPS)” may contribute to such a misunderstanding, however the study describes the plan to build up mining and manufacturing facilities to build one GE⊕-LPS initially, and then to significantly increase production to build multiple GE⊕-SPSs to be transferred to GEO to service the terrestrial energy market.

During the GE⊕-LPS study the technical and financial feasibility were tested, and no need for fundamental technological breakthroughs was identified, although many engineering challenges were identified. Most of the core technologies for lunar surface mining, beneficiation and fabrication operations are already in use or under development on Earth today. These technologies could be extrapolated and adapted to the lunar environment, delivered in modular form and managed tele-robotically on the lunar surface with a high degree of AI powered autonomy. Although no technological breakthroughs may be needed, due to the lack of experience operating in the lunar environment and direct in-situ access to lunar materials, substantial engineering development will be required.

Financially, the scaled version of the GE⊕-LPS – the GE⊕-SPS – was shown to not only be more economically attractive than a comparable Earth-launched SPS, but also cost-competitive with any terrestrial energy alternative. A break-even point, of the investment into the cislunar transportation system and the lunar manufacturing facilities is expected to be less than 20 years. A multi-national organisational approach to implementation would de-risk the initial investment while also addressing the regulatory issues of spectrum allocation, orbital positioning, lunar resources utilisation, energy distribution issues, and compliance with international treaties and laws.

If further research confirms this, the impact on future SBSP development would be significant. More importantly, by opening a new source of energy that is independent of Earth-based constraints, the impact on the global energy economy and society in general could grow to be as important as was the introduction of fossil fuels 200 years ago. Indeed, this will catalyse the transformation of the fossil fuel age into the space energy age. Perhaps as important, this could also lead to a reduction in geopolitical tensions over the control and distribution of energy and become a source of inspiration for future generations.

GE⊕-LPS: the Greater Earth Lunar Power Station

Manufacturing SPS components from lunar materials requires developing facilities on the Moon for automated mining and manufacturing processes. Astrostrom’s approach to realizing SBSP could reduce the amount of mass for a SPS launched from Earth by 80% or more as well as reducing costs and the related CO2 emissions. The establishment of industrial-scale, robotic beneficiation and processing plants will provide access to several other materials, which could become valuable to other users in the cislunar region.

If GE⊕-LPS proves to be technically viable and then successful at delivering energy to the lunar surface, it is foreseeable that the concept can be scaled up to manufacture large parts of SPSs from lunar resources to supply energy to Earth at a significant level. This would also create many other benefits in addition to providing sufficient clean energy for Earth, such as a commitment to achieving a peaceful energy transition, the development of a cislunar transportation system, mining, processing, and manufacturing facilities on the Moon and in orbit, resulting in a two-planet economy and the birth of a spacefaring civilization.

Video: Together to the Moon (7:12)

https://vimeo.com/949920017

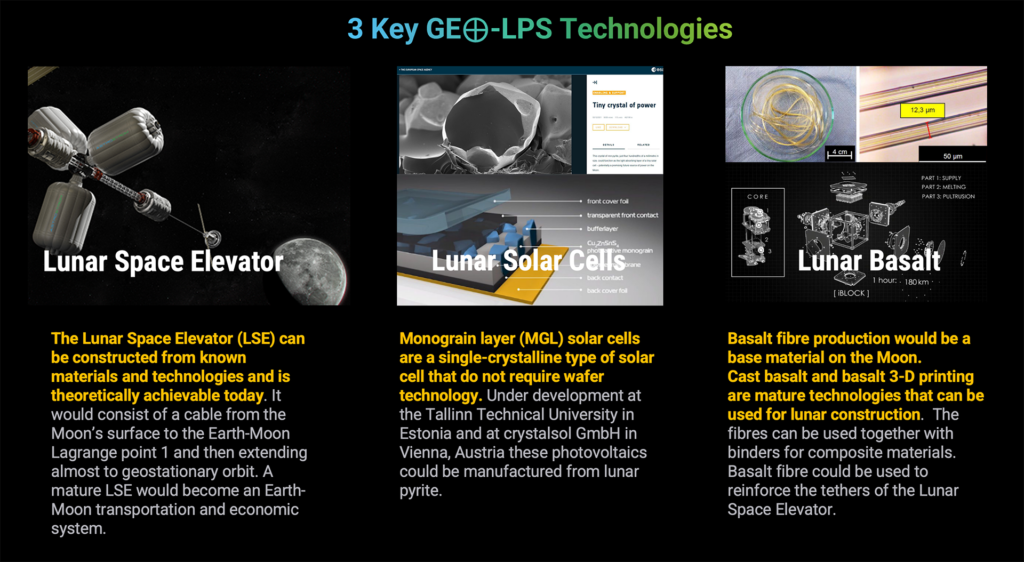

Astrostrom identified three key technologies. All are technically feasible and under development today.

- The Lunar Space Elevator (LSE) can be constructed from commercially available fibre materials such as Zylon and Dyneema, and constructed with known technologies. The LSE would consist of a cable reaching from the Moon’s surface to the assembly location at the Earth-Moon Lagrange point 1 (EM-L1) and then extending almost to geostationary orbit. A mature LSE would become an economic Earth-Moon transportation system with a commercial hub at EM-L1. [Astrostrom: JBIS] 5.

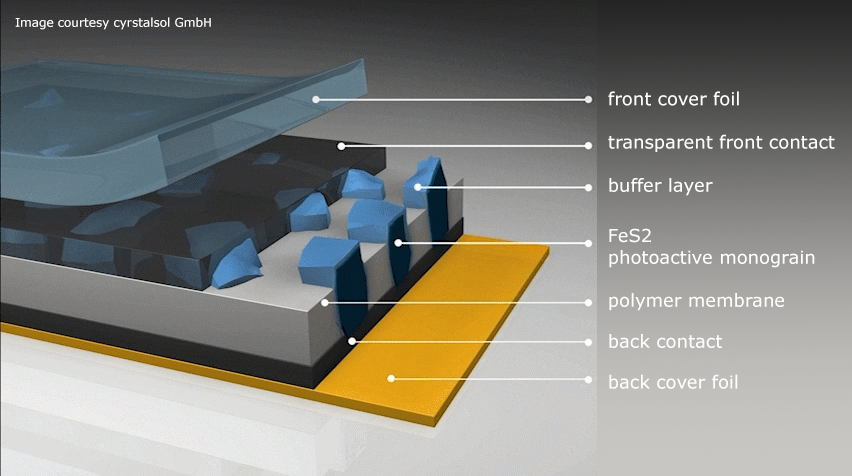

- Monograin layer (MGL) solar cells are a single-crystalline type of solar cell that do not require the use of wafer technology. Under development at the Tallinn Technical University in Estonia, this photovoltaic material could be manufactured from lunar pyrite synthesized from iron sulphide and sulphur [IAC-23-D3]6. MGL photovoltaics using copper, zinc, tin, sulphur, and selenium (CZTS) are currently being commercially produced at Crystalsol GmbH in Vienna, Austria. Their roll-to-roll production system could be modularized and sent to the Moon as compact, prefabricated factory modules ready for production.

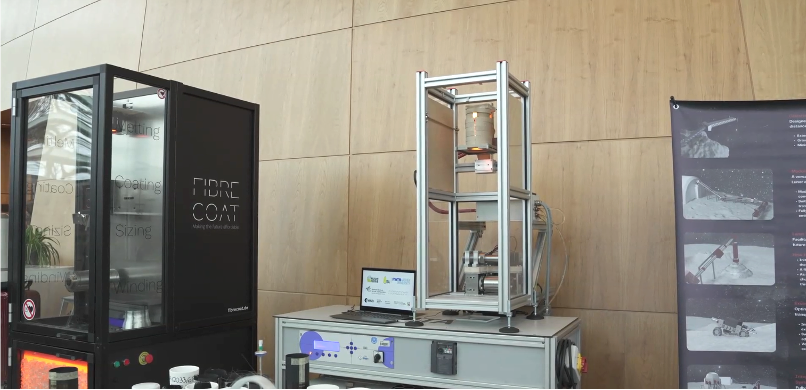

- Basalt fibre production would create a base construction material on the Moon. Cast basalt and basalt 3-D printing are mature technologies on Earth that can be adapted and used for lunar construction. Lunar basalt samples were collected by Apollo astronauts Eugene Cernan and Harrison Schmidt and returned to Earth. Basalt is quite abundant on the Moon, especially in the large, dark plains known as lunar maria. These maria are extensive basaltic lava flows that cover about 17% of the Moon’s surface. Nearly 26% of the near side of the Moon is basalt. Basalt fibre production from lunar regolith simulant is currently being researched at the ‘Institut für Textiltechnik der RWTH’ Aachen, Germany.

Article in JBIS – Journal of the British Interplanetary Society – Volume 76 2023 (5)

Monograin layer (MGL) diagram using pyrite FeS2

crystalsol GmbH MGL PV production facilities, Vienna, Austria – (using CZTS)

MoonFibre Production: Institut für Textiltechnik der RWTH Aachen

MoonFibre Production: Institut für Textiltechnik der RWTH Aachen

(Luxembourg Space Resources Week 2024)

As such, the initial Technology Readiness Level (TRL) of these key technologies is considered by Astrostrom to be relatively high, although obviously not yet tested in the lunar environment. The materials required for GE⊕-LPS include cast basalt and basalt fibre for the structural elements. Silicon, ilmenite and especially pyrite are considered for semiconductors and photovoltaics, whereas metals such as iron and aluminium will serve for the electrical connections. The establishment of industrial-scale beneficiation and processing plants will provide access to several other materials, which may become valuable to other users in the cislunar region. In addition to small amounts of Helium-3, large amounts of oxygen will be produced as a by-product which can be used in life support systems and as rocket propellant, thereby creating business cases for new cislunar enterprises. The GE⊕-LPS Final Report estimated the mass of the infrastructure needed to be delivered to the Moon at 5,500 MT.

Based on the GE⊕-LPS Final Report a GE⊕-SPS configuration for terrestrial energy power supply would have the following characteristics:

- Rated power: 1.44 GW

- Availability: 90%

- Power output to the grid: 1.125 GW

- Energy provided per year: 9,852,000 MWh

- Orbital mass: 6,886 MT

- Mass launched from Earth: 400 MT

- Area of photovoltaics: 12,348,193 m2

- PV efficiency: 13%

- Frequency of Wireless Power Transmission (WPT): 5.8 GHz

- Area of rectenna: 32,000,000 m2

- Operational lifetime: 30-45 years

- Deployed system cost (CAPEX): €2.54 billion

- Operating costs (OPEX) 30 years: €1.3 billion (€43.3 million/year)

Conclusion

GE⊕-LPS is being designed to provide plentiful electrical power for lunar activities; serve as a gateway between Earth and Moon operations; and be a prototype for future space settlement and tourism in cislunar space. As it is foreseen that the energy production functions of the GE⊕-LPS concept can be scaled to any dimension, larger versions could be positioned in Earth orbit to provide much needed clean, continuous solar electricity for terrestrial users. Driven by the ever-growing energy market on Earth, a two-planet economic system will emerge, which will dramatically lower the costs of transporting people and resources between LEO and the lunar surface, and accelerate the growth of many new cislunar businesses.

Astrostrom’s approach to SBSP, unites the aims of lunar development with widely shared aspirations for expanded space activities, while also addressing the critical energy and environmental needs of human civilization on Earth. The Astrostrom concept to manufacture SPS components in a large scale on the Moon is not an alternative to all other SPS proposals currently under development, but is about establishing a larger, more resilient and sustainable framework for this emerging and vital technology. As such, it should be immediately pursued diligently and consequently with all other SPS systems. Reaching the end of the fossil fuel age and the ecological limits of Earth’s biosphere, humanity must be intelligent about how to enable this energy and societal transformation.

Dr. Sanjay Vijendran, overseeing ESA’s SOLARIS program explains: (ESA, LPS, 2023) 7

“Launching large numbers of gigawatt-scale solar power satellites into orbit from the surface of the Earth would run into the problem of a lack of launch capacity as well as potentially significant atmospheric pollution. But once a concept like GE⊕-LPS has proven the component manufacturing processes and assembly concept of a solar power satellite in lunar orbit, it can then be scaled up to produce further solar power satellites from lunar resources to serve Earth. This would also create many other benefits in addition to providing sufficient clean energy for Earth, including the development of a cislunar transportation system, mining, processing, and manufacturing facilities on the Moon and in orbit resulting in a two-planet economy and the birth of a spacefaring civilisation.”

ESA SOLARIS on LinkedIn (https://lkdin.io/4FlI) 8

“We are pleased to finally share with you the full results of a visionary European Space Agency – ESA study called “Greater Earth Lunar Power Station”, or “GE⊕-LPS” for short, undertaken as part of ESA’s Open Space Innovation Platform Campaign on ‘Clean Energy – New Ideas for Solar Power from Space’, by Switzerland’s Astrostrom company.

The study envisages a solar power satellite constructed mainly from lunar resources (including Moon-manufactured solar cells) that could deliver megawatts of power down to receivers on the lunar surface, serving the needs of surface activities, including future crewed bases.

More importantly, the study lays out a vision for larger-scale, more cost-efficient and more environmentally-friendly solar power satellite production in the longer-term, if ESA’s SOLARIS R&D initiative confirms the feasibility of Space-based Solar Power for serving terrestrial clean energy needs. It envisages the development of a cis-lunar and surface infrastructure supporting largely-automated factories on the Moon for commercially-viable production of much of the hardware needed for solar power satellites that could then be launched from the Moon into Earth orbit where it would be assembled into power satellites to provide clean energy to terrestrial users.

Such industrialisation of the Moon for solar power satellite production would also create many other benefits in addition to providing abundent clean energy for Earth, including a clear-cut business case for the development of an expansive cislunar transportation system, mining, processing, and manufacturing facilities on the Moon and in orbit resulting in a two-planet economy and the birth of a spacefaring civilisation.

Although substantial engineering development would be required, the study found that solar power satellites produced on the Moon would not only be cheaper than any comparable Earth-developed solar power satellite, but that the electricity generated for Earth would also be cost-competitive with any terrestrial power alternative.”

Astrostrom GmbH

Astrostrom GmbH was incorporated in 2021 as a think-tank and systems integrator for industries, institutions, organisations, and individuals dedicated to developing and providing clean and inexhaustible energy from space to Europe and the world, through the utilization of extraterrestrial resources and advanced robotic technologies. The company conducts feasibility studies and visualization projects promoting the Space Energy Option and develops and promotes public outreach activities including technological demonstrations and cultural and educational events. The purpose of the company is to introduce, promote and expand an economic, technological and cultural dimension to the astronautical endeavours of mankind, with a focus on the generation of energy from space. It is especially strong in making video presentations of its research. It was hired by ESA to make their SOLARIS promotion video 9

Astrostrom is the German word for Astroelectricity coined by Michael Snead in his book with the same title about providing electricity from space.

References:

- ESA: OSIP, 2020, Campaign: Clean Energy – New Ideas for Solar Power from Space ideas.esa.int

- ESA: Nebula Archive: https://nebula.esa.int/content/ge%E2%8A%95-lunar-power-station

- Astrostrom: GE⊕-LPS Final Report: ESA Contract No: 4000136309/21/NL/GLC/ov.

https://astrostrom.ch/docs/GE⊕-LPS-Final-Report_June_2023.pdf - ESA Solaris:

https://www.esa.int/Enabling_Support/Space_Engineering_Technology/SOLARIS - Astrostrom: JBIS: The Lunar Space Elevator and the GE⊕-LPS

https://astrostrom.ch/jbis-the-lunar-space-elevator-and-the-GE⊕-LPS/ - IAC-23-D3, 2023, Pyrite based solar panel in-situ production on the Moon for Space-Based Solar Power, T. Raadik, et al.

- ESA: Lunar Solar Power Satellite 2023

https://www.esa.int/ESA_Multimedia/Images/2023/07/Lunar_solar_power_satellite - ESA: Announcement of GE⊕-LPS study on LinkedIn: https://lkdin.io/4ANI

- ESA Solaris video on YouTube.

https://www.youtube.com/watch?v=8ScTbb-43A4

ASTROSTROM is seeking strategic partners and investors to set up the Greater Earth Energy Organisation (GEEO) to implement SBSP.

To find out how you can participate in this unprecedented opportunity that will transform the Fossil Fuel Age into the Space Energy Age, please send us an inquiry.